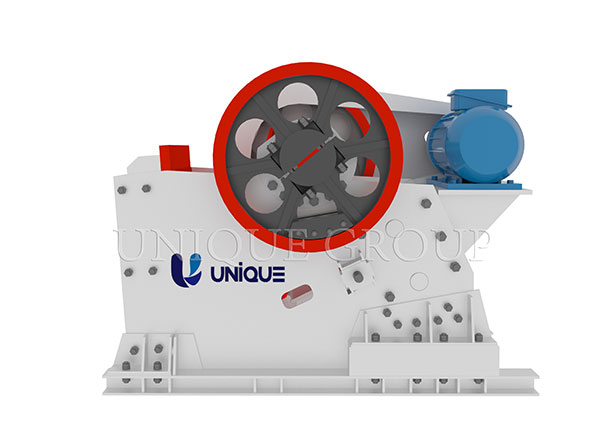

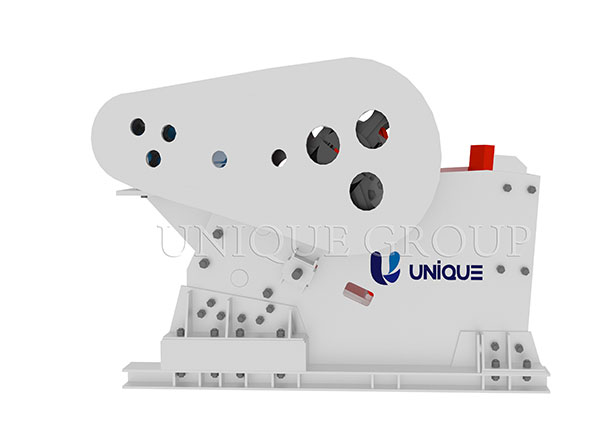

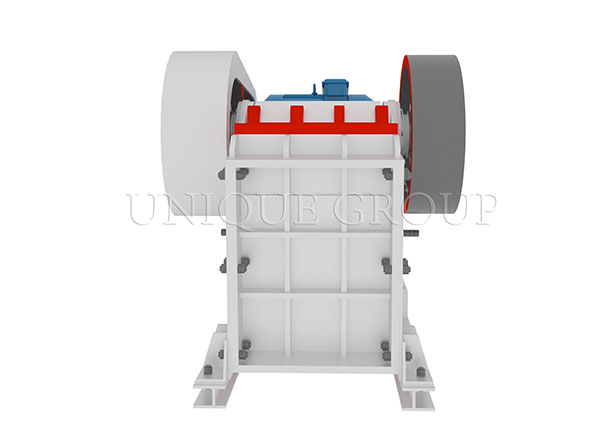

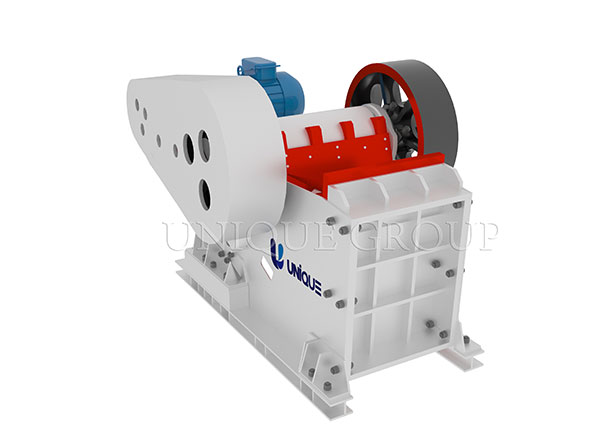

Jaw crusher Introduction:

Jaw Crusher Working Principle and Features:

Technical Parameter of Jaw Crusher

|

Model |

Feeding size |

Max feeding size |

Discharge range |

Capacity |

Shaft rotation speed |

Motor power |

Weight |

|

|

PE-150×250 |

150×250 |

125 |

10-40 |

1-3 |

250 |

5.5 |

0.8 |

720×660×850 |

|

PE-200×300 |

200×300 |

180 |

15-50 |

2-6 |

260 |

7.5 |

1.2 |

910×750×990 |

|

PE-250×400 |

250×400 |

210 |

20-60 |

5-20 |

300 |

15 |

2.8 |

1300×1090×1270 |

|

PE-400×600 |

400×600 |

340 |

40-100 |

16-60 |

275 |

30 |

7 |

1730×1730×1630 |

|

PE-500×750 |

500×750 |

425 |

50-100 |

40-110 |

275 |

55 |

12 |

1980×2080×1870 |

|

PE-600×900 |

600×900 |

500 |

65-160 |

50-180 |

250 |

55 |

17 |

2190×2206×2300 |

|

PE-750×1060 |

750×1060 |

630 |

80-140 |

110-320 |

250 |

110 |

29 |

2660×2430×2800 |

|

PE-800×1060 |

800×1060 |

640 |

130-190 |

130-330 |

250 |

110 |

29.8 |

2710×2430×2800 |

|

PE-900×1060 |

900×1060 |

685 |

230-290 |

230-390 |

250 |

110 |

33 |

2870×2420×2940 |

|

PE-900×1200 |

900×1200 |

750 |

95-165 |

220-450 |

200 |

110 |

52 |

3380×2870×3330 |

|

PE-1000×1200 |

1000×1200 |

850 |

195-265 |

315-500 |

200 |

110 |

55 |

3480×2876×3330 |

|

PE-1200×1500 |

1200×1500 |

1020 |

150-350 |

400-800 |

180 |

160-220 |

100.9 |

4200×3300×3500 |

|

PE-1500×1800 |

1500×1800 |

1200 |

220-350 |

500-1000 |

180 |

280-355 |

122 |

5160×3660×4248 |

|

PE-1600×2100 |

1600×2100 |

1500 |

300-400 |

1300-2200 |

160 |

350-380 |

150.6 |

6210×4013×4716 |

|

PEX-250×750 |

250×750 |

210 |

25-60 |

13-35 |

330 |

30 |

5.5 |

1380×1750×1540 |

|

PEX-250×1000 |

250×1000 |

210 |

25-60 |

16-52 |

330 |

30 |

7 |

1560×1950×1390 |

|

PEX-250×1200 |

250×1200 |

210 |

25-60 |

20-61 |

330 |

37 |

9.7 |

2140×1660×1500 |

|

PEX-300×1300 |

300×1300 |

250 |

20-90 |

16-105 |

300 |

55 |

15.6 |

2720×1950×1600 |

(Live chat)

(Live chat)