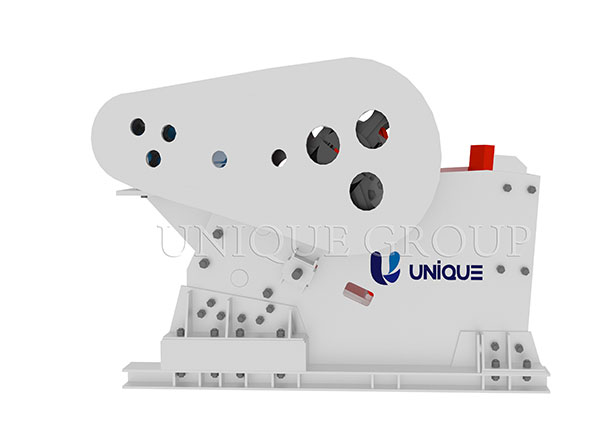

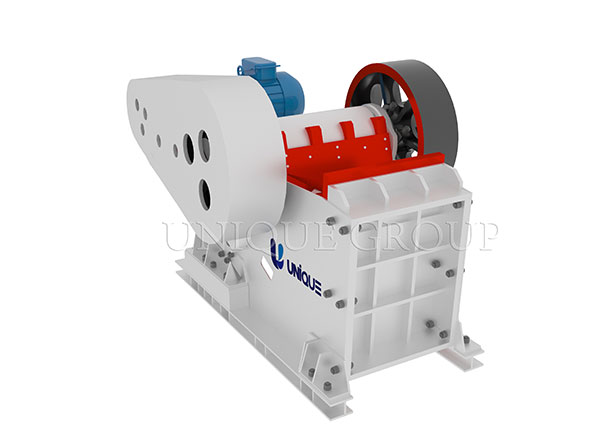

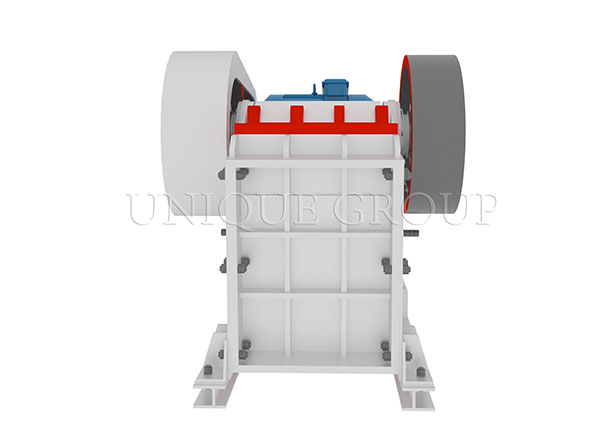

The working principle of European style PEW series jaw crusher:

The crushing method of European style PEW series jaw crusher is dynamic squeeze. The working principle is: the electro motor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Features of European style PEW series jaw crusher:

1. World-level manufacturing technology is adopted, and highest-level raw material is used.

2. Central lubricating device are installed on the machine, so the bearing is easy to be lubricated.

3. Adjustment of the discharge part is more convenient. The adjustment methods: gasket adjustment, hydraulic assistant adjustment, wedge block and wedge hydraulic adjustment.

4. More advanced movable jaw assembly lengthens life of crusher. Movable jaw assembly is made from cast piece with high-quality, is driven by two large flying wheels which are made from cast steel. Moreover, heavy eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher extremely reliable.

5. Integral cast steel structure is adopted for bearing seat. Integral cast steel bearing matches well with the crusher frame, at the same time, radial strength of the bearing seat is highly strengthened. However, the separate bearing seat does not have this advantage.

6. Finite element analysis technology is adopted to make the crusher much stronger.

7. Crusher chamber adopts "V" structure which could make actual feed width comply with the nominal one.

8. Bearing with larger model and higher load are used. All JC jaw crusher is equipped with larger bearing compared with same model of normal jaw crusher. Its higher load capacity and effective oil seal will lengthen the life of bearing.

9. A newly designed tooth-shape side plate, makes the available area of jaw plate longer, and enhances the capacity.

10. Pressing bar and support type are used to fix jaw plate.

11. Heavy type protecting plate is intalled for bearing seat, accidental damage of bearing seat is avoided.

12. Supporting bar under jaw plate protects movable jaw and frame from being worn down.

Specifications of European style PEW series jaw crusher:

|

Model |

Max. Feeding Size (mm) |

Adjustable Discharge opening (mm) |

Capacity (t/h) |

Motor Power (kW) |

Overall Dimensions (mm) |

Weight (t) |

|

PEW200×1300 |

150 |

10-30 |

12-35 |

30 |

1320X2150X1175 |

6 |

|

PEW250x1000 |

220 |

20-40 |

15-50 |

30 |

1400x1850x1310 |

5.6 |

|

PEW250x1200 |

220 |

20-40 |

20-50 |

37 |

1450x2150x1175 |

6 |

|

PEW400x600 |

350 |

35-85 |

15-70 |

37 |

1920x1460x1840 |

6.5 |

|

PEW860 |

720 |

100-225 |

200-500 |

132 |

3300x2320x3120 |

32 |

|

PEW1100 |

940 |

150-275 |

300-650 |

185 |

4140x2660x3560 |

59.2 |

(Live chat)

(Live chat)