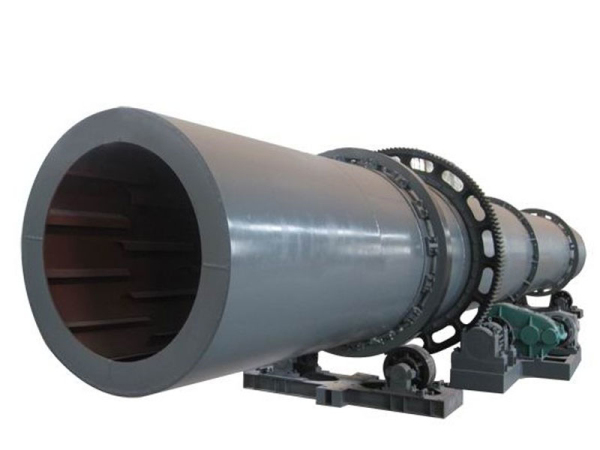

How to maintain the rotary dryer?

It is very important for the workers to know how to maintain the rotary dryer on the daily basis. Zhengzhou Unique Industrial Equipment Company would like to introduce several ways to maintain the rotary dryer.

1. If the moisture of the output product is still too high, you need to control the production capacity of the dryer and increase the supply of the fuel.

2. If there is abnormal noise coming out of the dryer, that’s because the dryer is jammed internally or the temperature inside the dryer is excessively high. If the reason is the jammed material, the worker should shut down the machine immediately and clean the chamber of the dryer. If the reason is the excessively high temperature inside the dryer, the worker should reduce the supply of the fuel to meet with the requirement of the normal production process.

3. If the rolling ring is shaking abnormally, that’s because the concave connector of the rolling ring is loose, and in that case, the worker should fasten the connector but not too tight.

4. If there is air leakage from the dryer, the low air pressure cannot give out produce normally. In that case, the worker should inspect and adjust the dryer according to the drawing.

5. If the gap between the big gear and small gear become larger, the worker should check the abrasion situation of them and change them into new ones if necessary.

(Live chat)

(Live chat)