Preliminaries before Ore Beneficiation

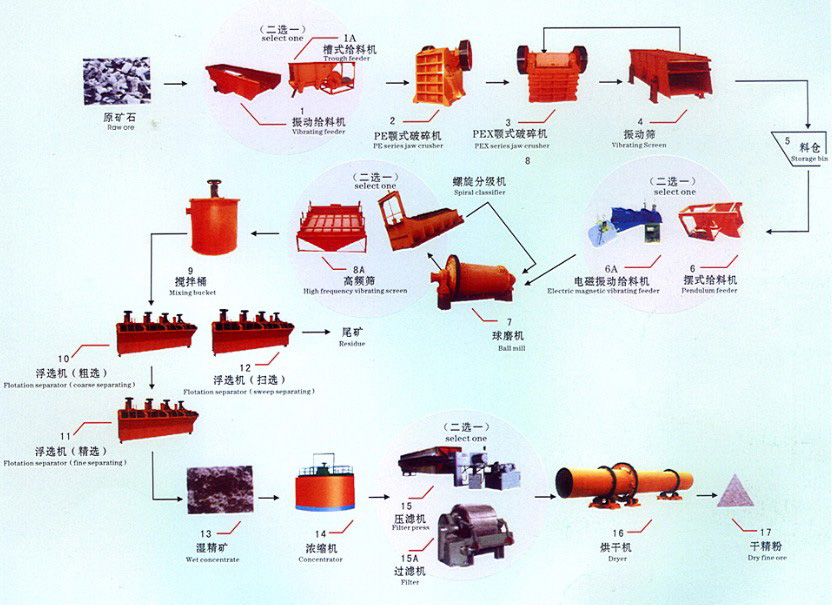

Generally, there are three stages of ore beneficiation process: preliminaries, ore beneficiation and dehydration. Here, we talk about the preliminaries before ore beneficiation.

The preparation work of raw materials before ore beneficiation includes smashing (including crushing and grinding), screening and classification, and sometimes, it also includes ore washing.

1. Crushing

Crushing refers to the process of crushing the ores of 500~1500mm quarried from the mines to the granularity of 5~25mm, and the crushing methods include squashing, breaking and splitting. Generally speaking, the crushing process can be divided into three stages: coarse crushing, medium crushing and fine crushing.

2. Grinding

Grinding is dominated by milling and impacting. This process can grind the crushed products to the size of 10~300μm. The grinding granularity is determined by the dip dyeing granularity of useful minerals in the ores and the adopted ore beneficiation method. The common ore grinding equipment includes rod grinding mill, ball mill grinder, autogeous mill and semi-autogeous mill. The energy consumption of grinding process is high and it usually accounts for about half of the total energy consumption of the ore beneficiation process.

3. Screening and classification

The process of screening materials to different sizes according to the size of the screen hole is called screening which is usually used for processing materials with coarse granularity. The process of classifying materials to different gradations according to the falling speed of particles in the medium (usually water) is called classification which is often used for materials with small granularity. Screening and classification are used for separating materials with the proper granularity or separate the materials into different granularity levels in the crushing process.

4. Ore washing

To prevent mud contained in the mineral raw materials from blocking the crushing and screening equipment, it is necessary to wash the ores. When raw materials contain soluble useful or harmful components, they should also be washed. The ore washing process can be carried out in a sand washing plant or the screening and classifier machine.

(Live chat)

(Live chat)