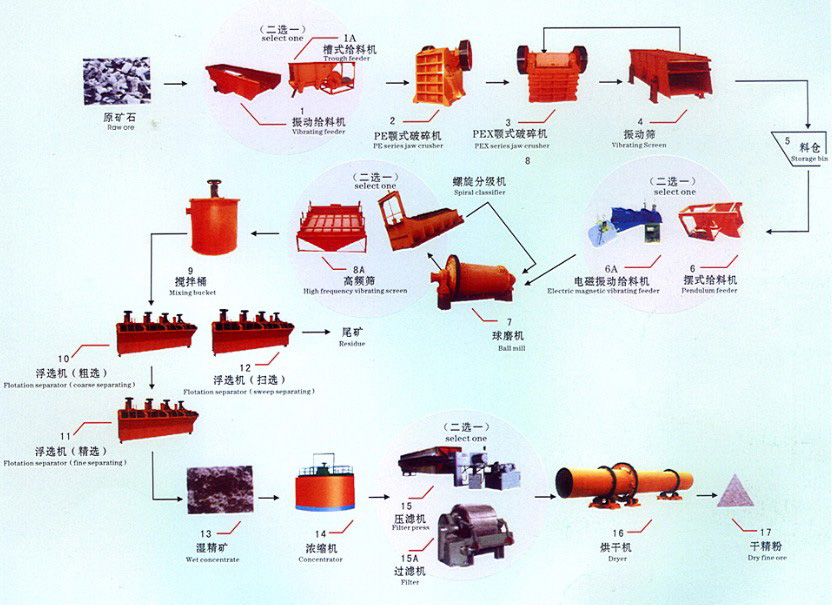

Hematite Ore Beneficiation Flow Chart

The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved. However, these single separation methods can not help to get ideal beneficiation efficiency. In recently decades, combination of magnetic separation and gravity separation, magnetic separation and floatation separation, gravity separation and floatation separation has been adopted to get high grade hematite iron concentrate.

For flow sheet combination of gravity separation can be used to get the rough hematite iron concentrate, and then magnetic separation can upgrade the concentrate from gravity separation further while floatation separation is involved in beneficiation of iron with fine inlay. Combination of magnetic separation and gravity separation is mainly used to improve the grade of iron mixture of magnetite and hematite while magnetic separator is used to get magnetite concentrate and gravity separation to get hematite concentrate. Combination of gravity separation, magnetic separation and floatation separation can be used for some hematite of complex composition. During this flow sheet, gravity separation is used to get coarse iron blocks, magnetic separation is used to get the fine iron granules and the floatation separation is used to get the iron powder inlay or to remove sulfur in hematite iron ore.

(Live chat)

(Live chat)